Technicial Specifications

MS90 SII ●

MS130 SII ●

MS170 SII ●

MS220 SII ●

MS270 SII ●

MS300 SII ●

MS320 SII ●

MS430 SII ●

MS500 SII ●

MS600 SII ●

MS700 SII ●

MS800 SII ●

MS900 SII ●

MS1100 SII ●

MS1300 SII ●

MS1500 SII ●

MS1700 SII ●

MS2000 SII ●

MS2300 SII ●

MS2400 SII ●

MS2900 SII ●

MS3300 SII ●

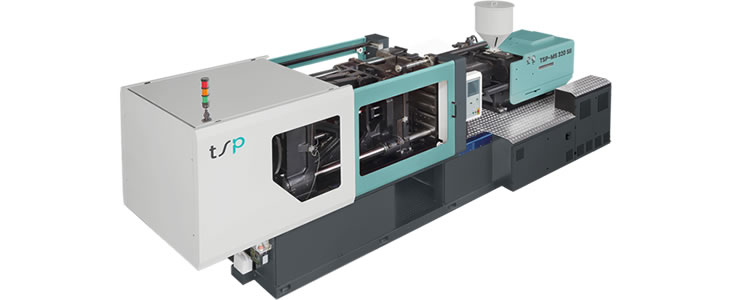

TSP MS Series

It provides the best and efficient performance in all kinds of injection processes with the advantages of a robust mechanical system, high precision and wide column spacing. MS offers options with a wide tonnage range from 90 tons to 4500 tons.